PA valves 调压阀 unloader Relief Pressure regulating valve 意大利P.A.安全阀 safety

高压清洗机的PA调压阀起到安全装置的作用。PA调压阀控制从高压泵中流出的水流方向。容积高压柱塞水泵始终输送水,无论喷枪是打开还是关闭。当喷枪关闭时,PA调压阀将水流重新引导回高压水泵的入口侧。这样可以防止危险的高压积聚,并防止零部件失效。高压清洗设备安装有被困压力卸料器或流量驱动卸料器。

喷枪启动、停止和引导高压清洗机喷嘴中的水流。挤压扳机释放压力。松开扳机会中断流向喷嘴的水流,尽管高压柱塞泵继续运行。如果没有释放这些水的出口,压力会继续增加。将导致非常危险的情况。

The pressure cleaner's unloader valve functions as a safety device. Unloader valves control the direction of the flow of water exiting the pump. A positive displacement pump always delivers water, regardless of whether the spray gun is open or closed. When the spray gun is closed, the unloader valve redirects the flow of water back to the inlet side of the pump. This prevents the build up of dangerously high pressure and guards against the failure of component parts. Pressure cleaners are installed with either a Trapped Pressure Unloader or a Flow Actuated Unloader.

Spray guns start, stop, and direct the flow of water from the pressure washer’s nozzle. Squeezing the trigger releases pressure. Releasing the trigger interrupts the flow of water to the nozzle, although the pump continues to run. Without an outlet for releasing this water, pressure would continue to build. A very dangerous situation would result.

PA调压阀

PA调压阀充当压力调节器,在压力清洁器系统中引导水流。当水停止从喷枪喷嘴流出时,PA调压阀会将其重定向到安全的压力出口。当清洁器处于“旁路模式”时,喷枪未释放的水被转移回压力高压柱塞泵的入口侧。然后,它通过高压水泵循环并返回PA调压阀的入口侧。水再次通过喷枪释放,或重定向到高压柱塞水泵。通过高压泵继续循环水的过程称为“循环”。

The Unloader Valve

Unloader valves function as “traffic cops” and pressure regulator that direct the flow of water in a pressure washer system. When water stops flowing from the nozzle of a spray gun, the unloader valve redirects it for a safe pressure outlet. When the cleaner is in “bypass mode,” water that is not released by the spray gun is diverted back to the inlet side of the pressure pump. It then circulates through the pump and back to the inlet side of the unloader valve. Water is once again either released via the spray gun, or redirected to the pump. The process of continued re-cycling of water through the pump is called “cycling.”

•“截留压力”PA调压阀是*常用的。这些阀门通过在高压柱塞泵输出端建立压力来感应并激活。截留压力阀启动旁路模式,直接响应高压柱塞水泵输出和喷枪之间软管中的建筑压力。它们通常简称为“压力”阀。当循环中断时,会产生压力峰值,滞留压力阀将水重新释放到喷枪中。操作人员应做好喷枪或喷枪杆上的“反冲”效应的准备,以免失控或受伤。

•“Trapped Pressure” unloader valves are the most commonly used. These valves sense and are activated by building pressure at the pump output. Trapped Pressure valves initiate bypass mode in direct response to building pressure in the hose between the pump output and the spray gun. They are often simply called “Pressure” valves. A spike of pressure results when cycling is interrupted and Trapped Pressure valves re-release water to the spray gun. Operators should be prepared for the “kickback” effect on the spray gun or wand to avoid loss of control or injury.

•“流量驱动”PA调压阀响应流向喷嘴的水流中断。这些阀门可感应到从阀门到喷枪的流量减少,并启动旁路回路作为响应。与截留压力阀不同,没有压力被捕获,因此当水重新释放时不会发生“反冲”。使用流量驱动PA调压阀时,操作员无法通过减小喷嘴的孔口尺寸来调节压力。流量驱动阀检测流量损失,并通过反复循环做出反应。

•“Flow Actuated” unloader valves respond to the interruption of water flow to the nozzle. These valves sense any decrease in flow from the valve to the spray gun and initiate the bypass loop in response. Unlike Trapped Pressure valves, no pressure is trapped, so no “kick back” occurs when water is re-released. With Flow Actuated unloader valves, operators cannot regulate pressure by downsizing the orifice size of nozzles. Flow Actuated valves detect the loss in flow, and react by cycling repeatedly.

虽然循环可以防止危险的压力积聚,但在旁路模式下会出现额外的安全问题。高压泵中的运动部件会产生摩擦和热量,这些摩擦和热量会传递到旁路的水流中。循环水可以迅速加热到危险温度,因为在旁路过程中没有冷水进入高压水泵。

Although cycling prevents the dangerous buildup of pressure, added safety concerns arise during bypass mode. Moving parts in the pump create friction and heat which is transferred to the water flow in bypass. Cycling water can quickly be heated to dangerous temperatures as no cool water enters the pump during bypass.

大多数高压清洗机高压柱塞泵可以承受 140º F 的温度。在较高的温度下,可能会损坏高压泵。高压柱塞水泵填料、柱塞、密封件,甚至外部旁路系统中的短旁路软管都可能损坏。散热阀提供一些保护,防止过多的热量积聚。它们确保当温度超过 145º F 时将冷水释放到高压水泵中。

Most pressure washer pumps can withstand temperatures of 140º F. At higher temperatures, damage to the pump can occur. Pump packings, plungers, seals, and even the short bypass hose in external bypass systems may be damaged. Thermal Relief Valves offer some protection against excessive heat buildup. They ensure cool water is released to the pump when temperatures exceed 145º F.

PA调压阀

PA调压阀 -22MPa-3130psi

PA调压阀 -32 MPa-4550 psi

PA调压阀 -42 MPa-5975 psi

PA调压阀 -110 MPa-16000 psi

安全阀

压力调节阀

压力调节阀 - 压缩空气控制

流量调节阀 - 调节阀

PA Valves

PA Unloader valves -22MPa-3130psi

PA Unloader valves -32 MPa-4550 psi

PA Unloader valves -42 MPa-5975 psi

PA Unloader valves -110 MPa-16000 psi

Relief valves

Pressure regulating valves

Pressure regulating valves - compressed air control

Flow regulator valves - Regulator valves

PA调压阀是确保往复式高压泵有效、高效运行的一个小而重要的部件。

An unloader valve is a small and essential part that ensures the effective, efficient operation of a high pressure pump.

什么是PA调压阀?

高压泵PA调压阀是一个很小的零件,通常尺寸在 4到5英寸之间。阀门从高压泵箱内释放滞留的水,从而使电机重新启动。如果PA调压阀无法释放水,积聚的压力可能会阻止电机启动。

高压水泵的阀门类型取决于机器的品牌和尺寸。有些通过设备压力开关侧面的拨动开关进行操作。其他的则在压力开关下方安装了一个整体阀。

What Is an Unloader Valve?

A high pressure pump unloader valve is a small part, usually sized between 4 and 5 inches. The valve releases trapped water from inside the high pressure triplex plunger pump’s tank, which allows the motor to restart. If the unloader valve cannot release the water, the built-up pressure might prevent the motor from starting.

An water high pressure pump’s valve type depends on the machine’s make and size. Some operate via a toggle switch on the side of the unit’s pressure switch. Others have an integral valve installed under the pressure switch.

PA调压阀的用途是什么?

在典型的往复式高压柱塞泵运行期间,机器的电动机驱动水箱充满水。该设备包含一个压力开关,该开关通过关闭电机的电源来响应水积聚。连接到电机轴的高压泵泵也停止。

当电机尝试重新启动时,滞留的水会产生限制其开启能力的负载。通过排出水,PA调压阀*大限度地减少了活塞上的负载,从而促进了重新供电过程。

What Is the Purpose of an Unloader Valve?

During the operation of a typical reciprocating water high pressure triplex plunger pump, the machine’s electric motor-driven tank fills with water. The device contains a pressure switch that responds to water accumulation by shutting off the motor’s power supply. The high pressure triplex plunger pump pump, which is attached to the motor shaft, also stops.

When the motor tries to restart, the trapped water produces a load that restricts its ability to switch on. By venting the water, the unloader valve minimizes the load across the piston, which encourages the repowering process.

PA调压阀位于何处?

PA调压阀位于小型往复式高压柱塞泵压力开关的顶部或内部。当开关关闭高压泵时,它会启动阀门。一根小管子或一根管子从止回阀(一种防止整个储罐排空的装置)延伸到PA调压阀。

较大的高压柱塞泵通常包含较大的PA调压阀。它由较小的先导阀释放的水压控制。在这种布置中,阀门通常位于高压泵旁边。

Where Is the Unloader Valve Located?

Unloader valves are located on top of or inside the pressure switch in smaller reciprocating water high pressure triplex plunger pumps. When the switch shuts the high pressure triplex plunger pump off, it actuates the valve. A small tube or pipe runs from the check valve — a device that keeps the entire tank from draining — to the unloader valve.

A larger water high pressure triplex plunger pump usually contains a larger unloader valve. It’s controlled by water pressure that’s released from a smaller pilot valve. In this arrangement, the valve typically sits next to the high pressure triplex plunger pump.

PA调压阀如何工作?

当高压泵水箱内的水压达到无法输送更多水的程度时,阀门开关会自动中断电机的电源供应。电源关闭后,PA调压阀打开并排出积聚的水。

当水箱压力回落到压力开关上的预定设置时,会导致开关再次跳闸。该动作导致PA调压阀的销松开,防止压缩水逸出到大气中。

How Does an Unloader Valve Work?

When the water pressure within the high pressure triplex plunger pump tank arrives at the point where it cannot deliver any more water, the valve switch automatically disrupts the power supply to the motor. After the power supply turns off, the unloader valve opens and vents the accumulated water.

When the tank pressure drops back down to the predetermined setting on the pressure switch, it causes the switch to trip again. This action results in the release of the unloader valve’s pin, preventing the escape of compressed water into the atmosphere.

如何更换PA调压阀

PA调压阀故障是导致高压泵无法正常运行的*常见问题之一。当水无法从储罐中逸出时,积聚的压力通常会阻碍设备重新启动的能力。

当PA调压阀发生故障时,它变得无法打开或关闭。打开的阀门释放出连续的泄漏水流。关闭的阀门会导致明显的压力积聚,从而限制泵的内部组件。当内部部件无法移动时,这会阻止发动机轴打开。

您应该尽快更换有故障的卸荷阀,以免它们影响其他关键高压泵部件。在下面了解有关如何更换PA调压阀的更多信息。

How to Replace an Unloader Valve

A malfunctioning unloader valve is one of the most common issues that prevents a high pressure triplex plunger pump from operating properly. When the water cannot escape from the tank, the built-up pressure often hinders the unit’s ability to restart.

When the unloader valve malfunctions, it becomes unable to open or close. Open valves release a continuous stream of leaking water. Closed valves result in significant pressure buildups that can restrict the pump’s internal components. When the interior components can’t move, this prevents the engine shaft from opening.

You should replace faulty unloader valves as soon as possible before they impact other critical high pressure triplex plunger pump components. Learn more about how to replace an unloader valve below.

开始需要什么

各种高压水泵都有不同类型的PA调压阀。无论您是使用压力控制器侧面的拨动开关,还是直接安装在装置上的阀门,这两种类型都需要相同的材料进行更换:

十字螺丝刀或平头螺丝刀

活动扳手

可调钳

剪钳

螺纹润滑剂

新型PA调压阀

安全眼镜

What You Need to Get Started

Various water high pressure triplex plunger pumps have different types of unloader valves. Whether you’re working with a toggle switch on the side of the pressure controller or a valve that mounts directly to the unit, both types require the same materials for replacements:

A Phillips or flathead screwdriver

An adjustable wrench

Adjustable pliers

Snipping pliers

Thread lubricant

The new unloader valve

Safety glasses

PA调压阀更换步骤

首先,打开排水阀给水箱减压。压力释放后,识别PA调压阀。它连接到将水输送到再循环泵的软管上。

接下来,是时候拆下旧阀门了。

请按照下列步骤操作:

1.拔下高压泵插头。

2.拆下进入阀门的管路。

3.如果阀门有,请使用可调钳或扳手卸下快速连接接头。

4.断开压力开关的电线。

5.拆下阀门。

Unloader Valve Replacement Steps

First, open the drain valve to depressurize the tank. After the pressure releases, identify the unloader valve. It’s connected to a hose that transfers water to the recirculation pump.

Next, it’s time to remove the old valve. Follow these steps:

1.Unplug the high pressure triplex plunger pump.

2.Remove the line going into the valve.

3.Use the adjustable pliers or a wrench to remove the quick-connect fitting if the valve has one.

4.Disconnect the wires from the pressure switch.

5.Detach the valve.

拆下旧阀门后,您可以按照以下说明安装新阀门:

1.在新阀门上涂上螺纹润滑剂。

2.用剪线钳剪掉少量线,确保连接干净。

3.连接线路。

4.重新连接快速连接接头。

5.安装新阀门。

6.根据泵制造商规定的压力调整新PA调压阀上的张力。

After removing the old valve, you can install the new one with these instructions:

1.Apply thread lubricant to the new valve.

2.Cut a small amount of the line with the snipping pliers to ensure a clean connection.

3.Connect the line.

4.Reattach the quick-connect fitting.

5.Attach the new valve.

6.Adjust the tension on the new unloader valve according to the pump manufacturer’s specified pressure.

PA调压阀 PA Unloader valves

PA Unloader valves -22MPa-3130psi

VB200-180 ZERO-ZEROED OUTLET PRESSURE, IN BYPASS

VB 200/150-VB200/70

VB 140/160

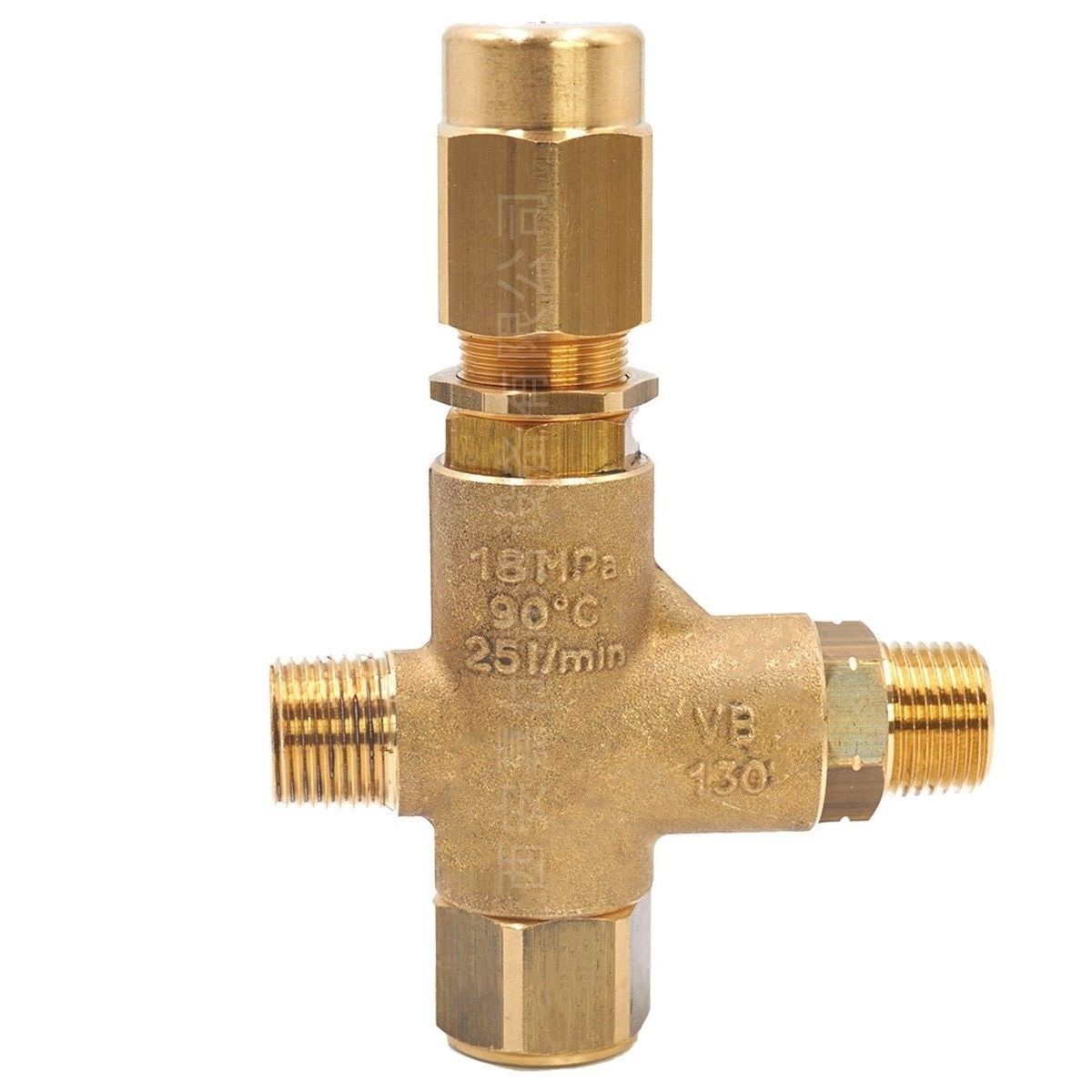

VB 130 PA UNLOADER VALVE

VB130-VB3-VB7-VB75 PLASTIC KNOB

VB20-160-VB30-220 ZERO-ZEROED OUTLET PRESSURE, IN BYPASS

VB20-160 ZERO WITH MICRO-SWITCH-ZEROED OUTLET PRESSURE, IN BYPASS

PULSAR RV- VALVE 3/8 BSP F - VITON O-RING

VB 450 - 200 - PA UNLOADER VALVE

VB 3- PA UNLOADER VALVE

VB 35 - BANJO CONNECTION - HOLLOW SCREW FITTING

VB 35 - BANJO CONNECTION- HOLLOW SCREW FITTING- ADJUST.INJECTOR

VB 5 - PA UNLOADER VALVE

VB 56 - BANJO CONNECTION - HOLLOW SCREW FITTING -OUT. 3/8 BSP F F

VB 56 - BANJO CONNECTION - HOLLOW SCREW FITTING -OUT. 3/8 BSP M

VB 7 - PA UNLOADER VALVE

VB 7 WITH INJECTOR

VB 75 - BANJO CONNECTION - HOLLOW SCREW FITTING

VB 8

VB 8 WITH MICRO-SWITCH-PR5

VB 8 WITH MICRO-SWITCH-PR16

VB 9

VB 9 WITH KNOB AND PANEL FITTING

VB 9 WITH KNOB AND MICRO-SWITCH

VB 10 WITH KNOB

VB 80A/150 - ATEX--AI 303-

PA调压阀PA Unloader valves -32 MPa-4550 psi

PULSAR ZERO WITH KNOB AND MICRO-SWITCH -ZEROED OUTLET PRESSURE, IN

BYPASS

VB80/280 ZERO - VALVE WITH ZEROED OUTLET PRESSURE, IN BYPASS

VB80/280 ZERO WITH KNOB AND MICRO-SWITCH - VALVE WITH ZEROED OUTLET PRESSURE, IN BYPASS

PULSAR RV - PA UNLOADER VALVE

PULSAR RV - BYPASS VALVE WITH KNOB

PULSAR RV - PA UNLOADER VALVE -NICKEL-PLATED BRASS

PULSAR RV + 1/4 BSP F GAUGE PORT

PULSAR RV WITH KNOB/ GAUGE PORT

PULSAR RV WITH MICRO-SWITCH/ KNOB

PULSAR RV WITH MICRO-SWITCH

PULSAR RV - UNLOA.VAL. WITH EASY STARTER AND KNOB

VB 280 WITH KNOB

VB 285 WITH KNOB - BANJO CONNECTION - HOLLOW SCREW FITTING

VB 85/180 - VB 85/310 WITH GAUGE PORT

VB 85 R/180 - VB 85 R/310 --PA UNLOADER VALVE

VB 85 RV/180 - VB 85 RV/310-UNLOADER VALV. WITH KNOB

VB85 RV/310 UNLOA.VAL. WITH MICRO-SWITCH

VB33 - PA UNLOADER VALVE

VB33- HT 28MPA - PA UNLOADER VALVE FOR HOT TEMPERATURE WATER

VB 200/280 - PA UNLOADER VALVE

VB 450 - 300 - PA UNLOADER VALVE

VB 80A/280 - AISI 303 ATEX

VB 80 /150-280 - AISI 316 -VITON O-RINGS

VB 80A/150- 280 ATEX -AISI 316 -VITON O-RINGS

VB 23 - AISI 303 -VITON/EPDM O-RINGS

VB 26 - AISI 316 -VITON O-RINGS- PA UNLOADER VALVE

PA调压阀PA Unloader valves -42 MPa-5975 psi

PULSAR ZERO - VALVE WITH ZEROED OUTLET PRESSURE, IN BYPASS

VB 350 PA UNLOADER VALVE WITH KNOB

VB 350 S

VB 350 WITH KNOB AND MICROSWITCH

VB 36

VB36- HT 39MPA - PA UNLOADER VALVE FOR HOT TEMPERATURE WATER

VB 80/150 - 280 - 400 - AISI 303

VB 80/150 - 280 - 400 - AISI 303 -VITON O-RINGS

VB 80/280- 400 - NORSOK- UNLOADER VAL. DUPLEX SST - VITON O-RINGS

VB 43 - AISI 303

VB23A-VB26A-VB33A- VB43A - VALV BYPASS ATEX

PA调压阀PA Unloader valves -110 MPa-16000 psi

VB 16

VB 53 - AISI 303

VB 250/500 - PA UNLOADER VALVE AISI 303

VB 83 - PA UNLOADER VALVE AISI 303

VB60/600-400-250 ZERO - VALVE WITH ZEROED OUTLET PRESSURE, IN BYPASS

VB60/600 ZERO WITH MICRO-SWITCH- VALVE WITH ZEROED OUTLET PRESSURE,IN BYPASS

VB40/1000 ZERO - VALVE WITH ZEROED OUTLET PRESSURE, IN BYPASS

STR -ADJUSTING BYPASS NEEDLE

浅析PA调压阀UNLOADLER溢流阀安全阀SAFETY对高压泵柱塞水泵清洗机设备的重要性

浅析阀门对高压泵清洗设备的重要性

随着高压柱塞水泵清洗机的使用领域不断增大,商场的需要量也不断增大。

尤其在工业清洗领域,由于工业清洗越来越被我们重视,所以该设备被广泛推广和使用。

当前高压清洗机已经成为工业清洗领域中首选的清洗设备,并且逐步向系统化和主动化进行演化。

而经过对高压水发生设备进行远程控制,即可结束高压水射流清洗的主动化。

远程主动控制PA调压阀是由压力变送器测量出高压水发生设备的出口压力,并将测量值转换为数字信号,传递给控制系统,控制系统根据需要宣布指令,启闭电动设备,电动设备根据控制系统的指令驱动P.A.调压溢流阀,从而结束高压水泵清洗设备的压力调度。

定压溢流作用:在定量泵节约调度系统中,定量泵供给的是安稳流量。

当系统压力增大时,会使流量需要减小。

此时PA unloader valve打开,使剩余流量溢回油箱,确保PA调压溢流阀进口压力,即高压柱塞泵清洗设备泵出口压力安稳(阀口常随压力不坚定打开)。

稳压作用:PA调压阀串联在回油路上, PA溢流阀发生背压,运动部件平稳性增加。

系统卸荷作用:在P.A.PA调压阀的遥控口串接溢小流量的电磁阀,当电磁铁通电时,PA unloader valve的遥控口通油箱,此时液压泵卸荷。

PA调压阀此时作为卸荷阀运用。

安全保护作用:高压泵清洗机系统正常工作时,阀门关闭。只需负载逾越规则的极限时打开溢流,进行过载保护,使系统压力不再增加。

高压水泵清洗设备之所以能够在额定工作压力下的任意工作压力工作,都是PA调压阀在发挥作用。PA调压阀是确保和结束这一工作的重要调度组织。

由于大多数的清洗机配备的高压水发生设备都归于定流量容积泵,所以在额定工作压力以下的任意压力工作时,都会伴跟着溢流。

而PA调压阀是能够一起结束高压清洗机高压水发生设备调压和溢流的设备,即称为P.A. unloader valve。

Relief valves

VS 30

VS 100 - AISI 316 - VITON O-RINGS

VS 160

VS 450-200

VS 140 - VS 240

VS 170 - VS 220 -1 INLET PORT

VS 170 - VS 220 - 2 INLET PORTS

VS 200/200

VS 28 / 1 - 2 – 3

VS 28 / 1 - 2 PRESSURE ADJUSTED

VS 80/150 - AISI 303 ATEX

VS 80/150-280 AISI 316 - VITON O-RINGS-ATEX

VS 23 AI303- VS23- DUPLEX VS 26 - AISI 316 - VITON O-RINGS

VS 450-300

VS 310 -1 INLET PORT

VS 350

VS 360

VS 24 - VS 43 - AISI 303

VS 26A - VS 43A – ATEX

VS 80/400 - AISI 303 – ATEX

VS 80/280-400 - NORSOK -SST. DUPLEX - VITON O-RINGS

VS 500-VS 500/310

VS 500- PRESSURE ADJUSTED VALVE

VS 500- SST

VS 660

VS 1100

"VS 1200 FL" POP-OFF VALVE

泄压阀

泄压阀又名 安全阀(safety valve)根据系统的工作压力能自动启闭,一般安装于封闭系统的设备或管路上保护系统安全。当设备或管道内压力超过泄压阀设定压力时,即自动开启泄压,保证设备和管道内介质压力在设定压力之下,保护设备和管道,防止发生意外。

编辑本段分类泄压阀结构主要有两大类:弹簧式和杠杆式。弹簧式是指阀瓣与阀座的密封靠弹簧的作用力。杠杆式是靠杠杆和重锤的作用力。随着大容量的需要,又有一种脉冲式泄压阀,也称为先导式泄压阀,由主泄压阀和辅助阀组成。当管道内介质压力超过规定压力值时,辅助阀先开启,介质沿着导管进入主泄压阀,并将主泄压阀打开,使增高的介质压力降低。

操作方法泄压阀开启压力的调整

1、泄压阀出厂前,应逐台调整其开启压力到用户要求的整定值。若用户提出弹簧工作压力级,则按一般应按压力级的下限值调整出厂。

2、使用者在将泄压阀安装到被保护设备上之前或者在安装之前,必须在安装现场重新进行调整,以确保泄压阀的整定压力值符合要求。

3、在铭牌注明的弹簧工作压力级范围内,通过旋转调整螺杆改变弹簧压缩量,即可对开启压力进行调节。

4、在旋转调整螺杆之前,应使阀进口压力降低到开启压力的 90%以下,以防止旋转调整螺杆时阀瓣被带动旋转,以致损伤密封面。

5、为保证开启压力值准确,应使调整时的介质条件,如介质种类、温度等尽可能接近实际运行条件。介质种类改变,特别是当介质聚积态不同时(例如从液相变为气相),开启压力常有所变化。工作温度升高时,开启压力一般有所降低。故在常温下调整而用于高温时,常温下的整定压力值应略高于要求的开启压力值。高到什么程度与阀门结构和材质选用都有关系,应以制造厂的说明为根据。

6、常规泄压阀用于固定附加背压的场合,当在检验后调整开启压力时(此时背压为大气压),其整定值应为要求的开启压力值减去附加背压值。

特点1、准确且保持不变的安全稳定压力,一旦超压,泄压阀能充分打开及时泄压。

2、关闭速度可调,消除压力波动。

3、隔膜传动机构将操作滞后现象减小到*小。

4、它可安装在任何位置,不用改变压力设定值或从管路上拆除就可进行维修和检查。

Pressure regulating valves

VRP 175

VRP 450-200

VRP 200

VRP 280

VRP 26 - AISI 316 - VITON O-RINGS

VRP 450-300

VRP 350

VRP 23 - VRP 43 - AISI 303

VRP 600

Pressure regulating valves - compressed air control

VRPP 170 AIR-CONTROLLED

VRPP 450-200 AIR-CONTROLLED

VRPP 33 - HT AIR-CONTROLLED

VRPP 26 - AISI316 AIR-CONTROLLED

VRPP 200-280 AIR-CONTROLLED

VRPP 600 - AISI 303 AIR-CONTROLLED

注:本文字介绍中的图片仅供参考,不予文字内容一一准确对应,具体以实物为准。