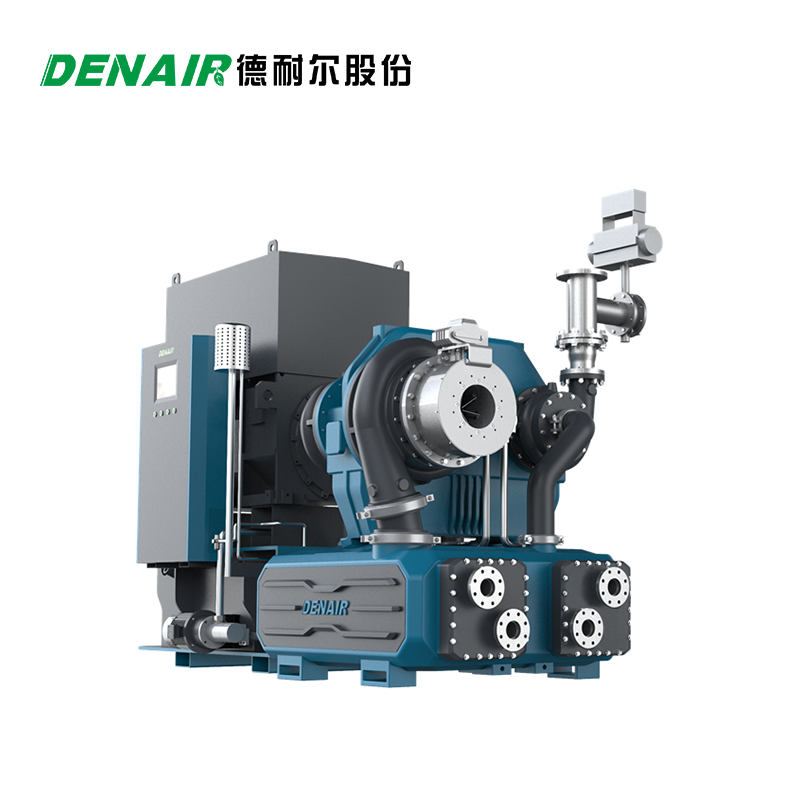

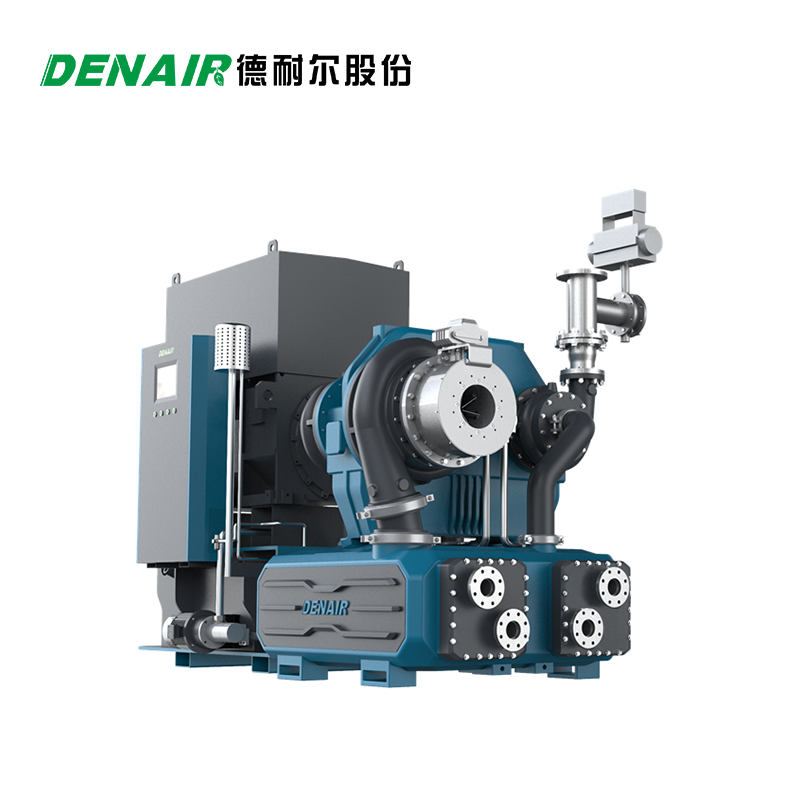

离心式压缩机

CENTRIFUGE COMPRESSOR

整体铸件齿轮箱-模块化集成装配

Integral casting gearbox-Modular integrated assembly

水平剖分式齿轮箱与各级蜗壳一体铸造,冷却器箱体整体铸造,模块化设计。与焊接齿轮箱分体式结构相比,主机机构强度更高、加工面更少、运行更可靠,各级蜗壳与齿轮箱体无装配误差、无变形、噪音低、振动小。与整体铸造相比,加工、装配、运输、现场安装、维护更加简便,在主机需要返厂大修的情况下,整体铸件需要更大起吊设备且破坏安装基础导致二次安装,而模块化的设计则完美解决这一问题。

The horizontallys plit gearbox is integrally cast wit h the wolutes at all stages, and the cooler box is integrally cast wit h a modular design. Com pa red with the split structure of the welded gearbox,the main engine mechanism has higher strength, fewer processing surfaces, and more reliable operation, There is no assem bly error, no deformation, low noise and low vibration between the volute and the gear box at all s ta ges. Co mpared with integral casting, processing, assem bly, tra ns portat ion, on-site installation and maintenance are sim pler. When the main engine needs to be returned to the factory for overhaul, the integral casting requires la rger lifting, equipment and destroys the installation foundation,resulting in secondary installation. The modular design it perfectlysowes this pro blem.