分子筛变压吸附利用分子筛对氧气和氮气吸附能力的差异以及吸附容量随吸附压力变化而变化的特性生产出以医疗、保健为目的医yong氧,具有清洁、取用方便等特点。为简单便捷获取呼吸用氧,利用分子筛变压吸附原理设计了一种微型yi制氧设备。方法:在分析分子筛制氧设备工作流程的基础上,给出了设备详细的气路和电路设计。原料空气经三级过滤处理后由无油空压缩机增压、冷凝器降温处理后经换向控制阀进入装有分子筛的吸附塔,空气中的氮气、二氧化碳、水蒸气被吸附剂选择吸附,氧气则穿过吸附塔进入储氧罐,经浓度、流量和压力检测后作为产品气体输出。利用单片机定时控制换向阀的换向切换,实现加压吸附、均压和解吸附的流程。还设计了设备运行过程中的信号检测、人机信息交互、故障诊断和报警系统等功能。结果:产品氧气浓度在90%以上,在小流量输出时浓度可达96%。整机噪声在55dB以下,具有计时、报警、血氧与脉率检测和雾化给药等功能。结论:合理选择设备部件、控制器件及创新的结构设计,该制氧机出氧浓度和压力稳定、噪声低,性价比高,运行安全可靠。

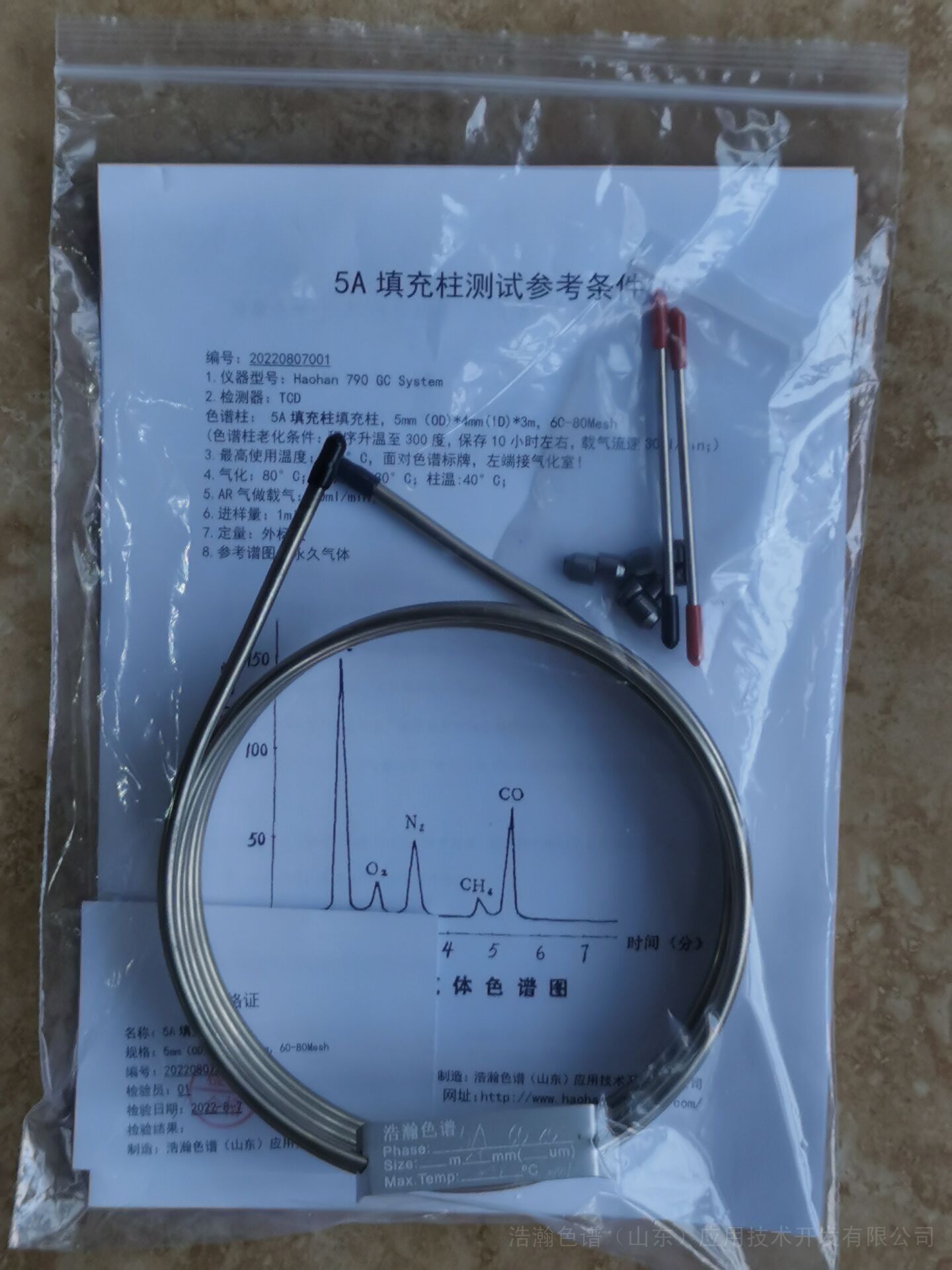

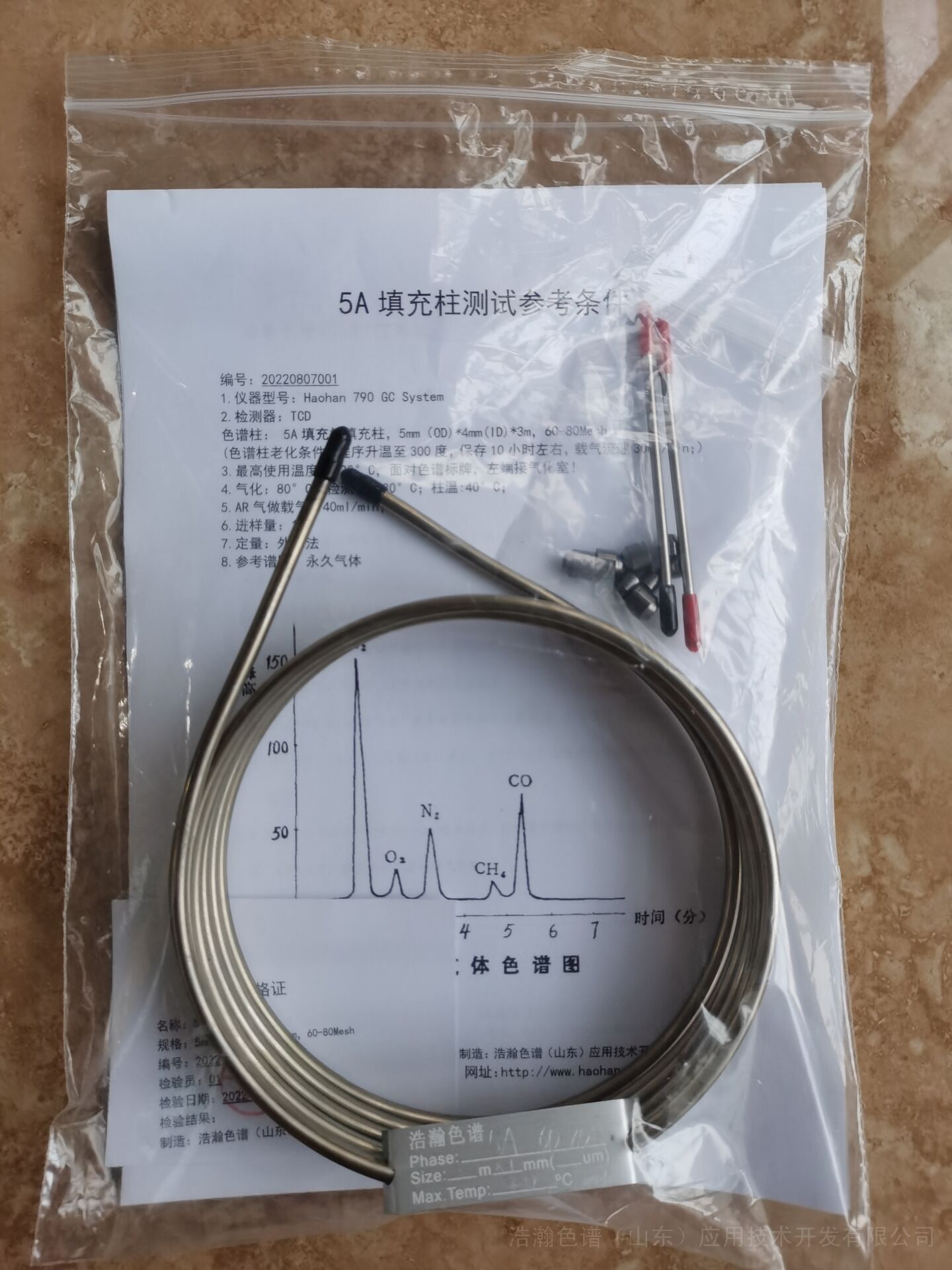

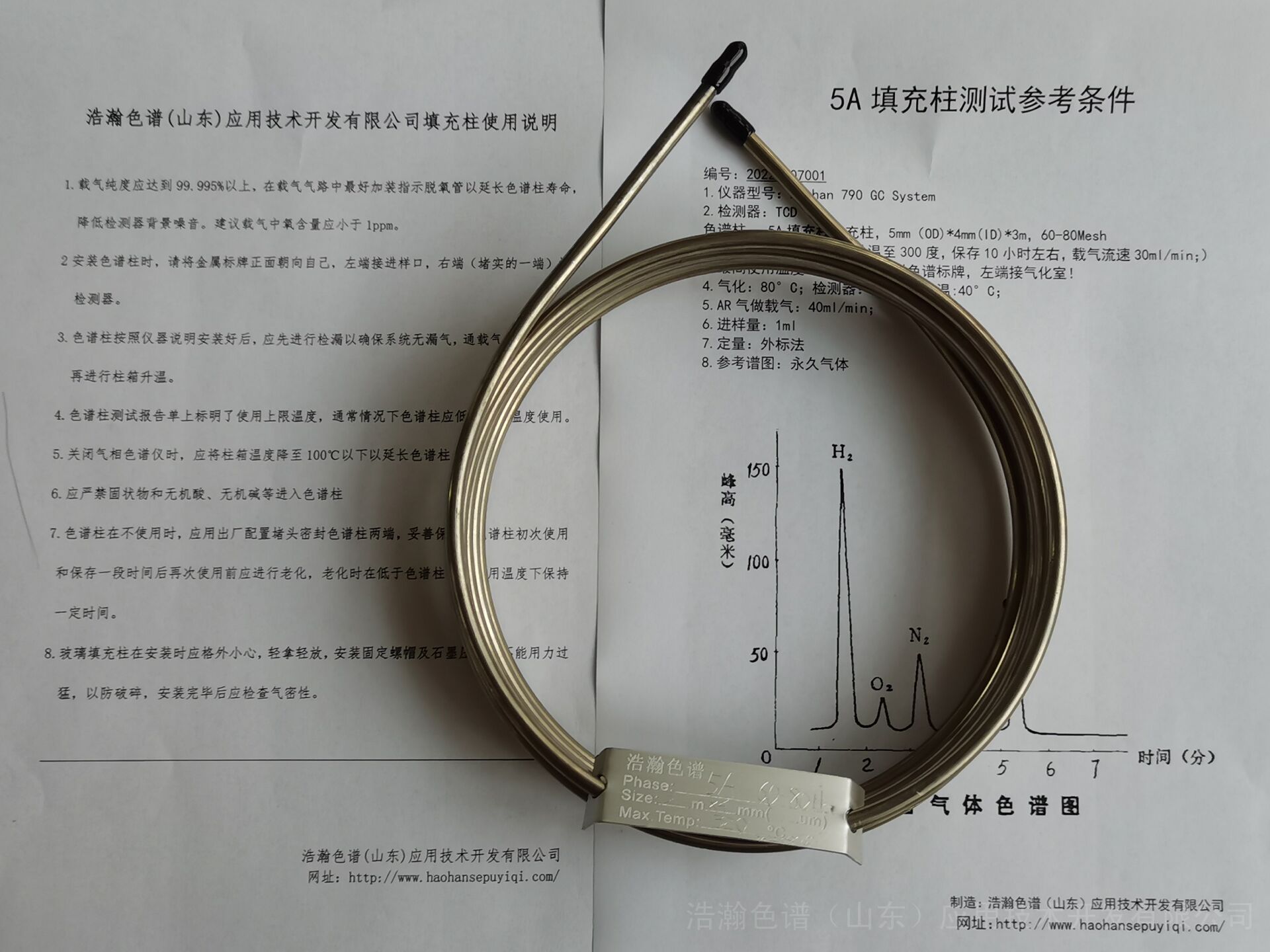

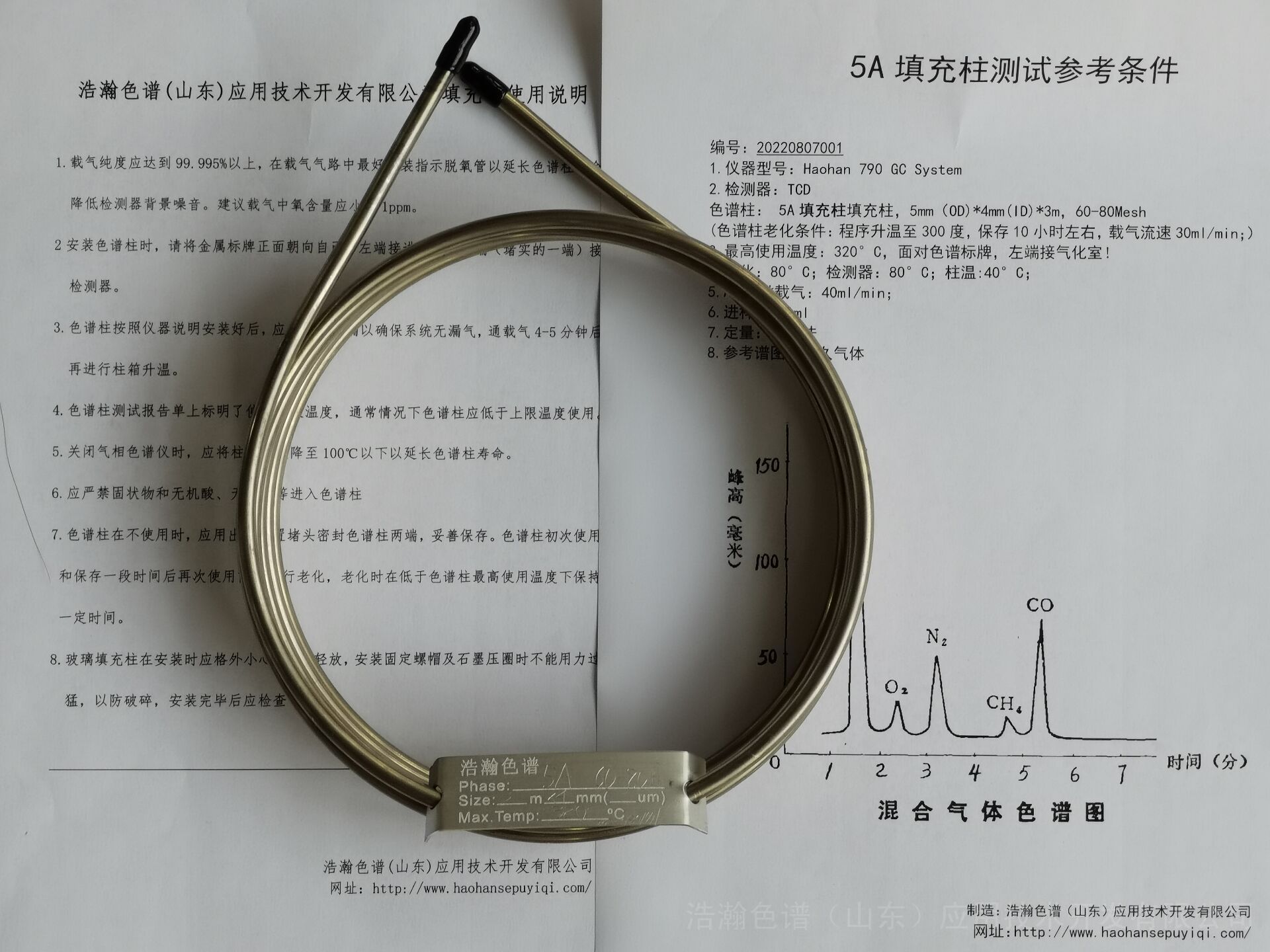

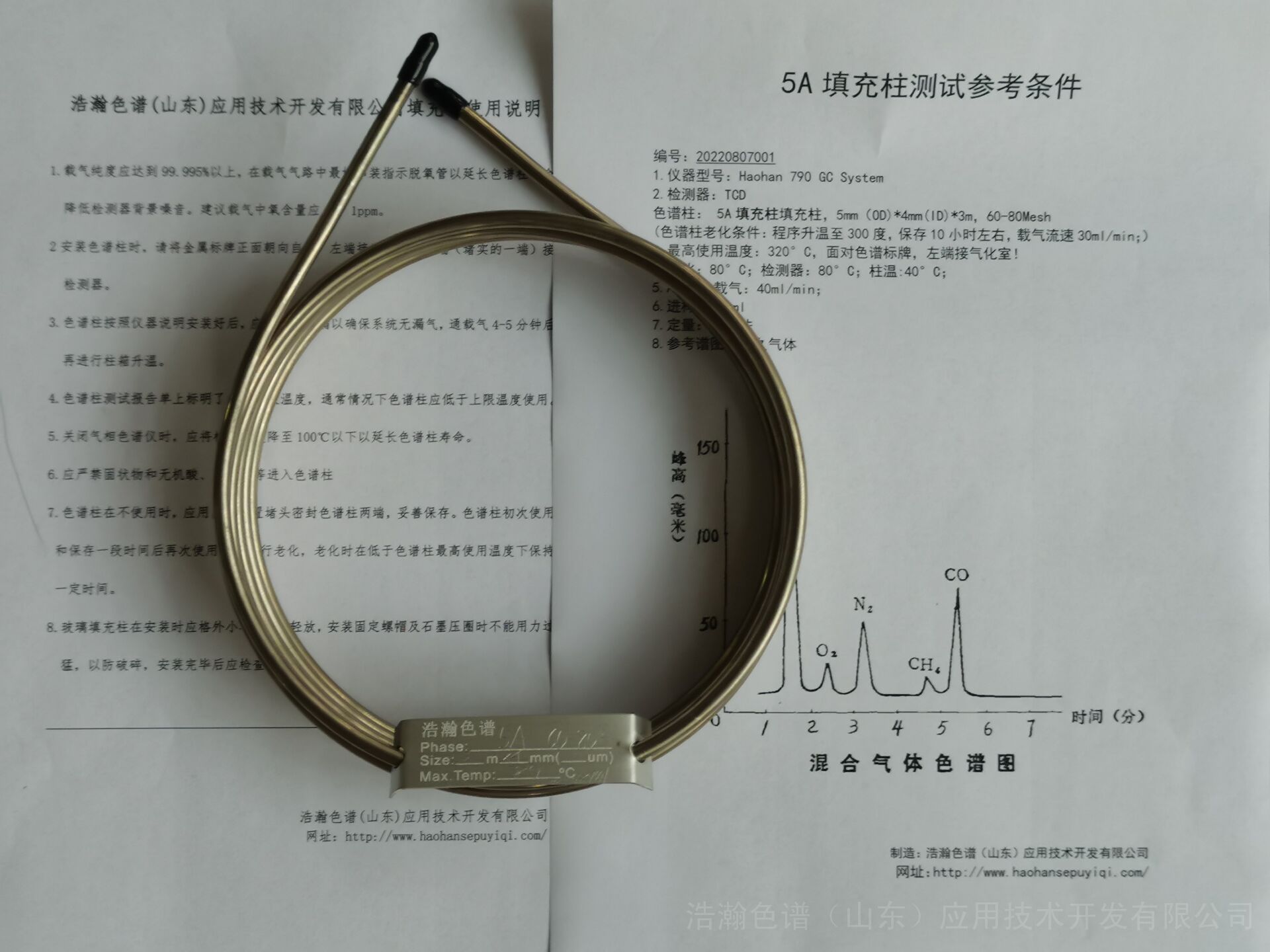

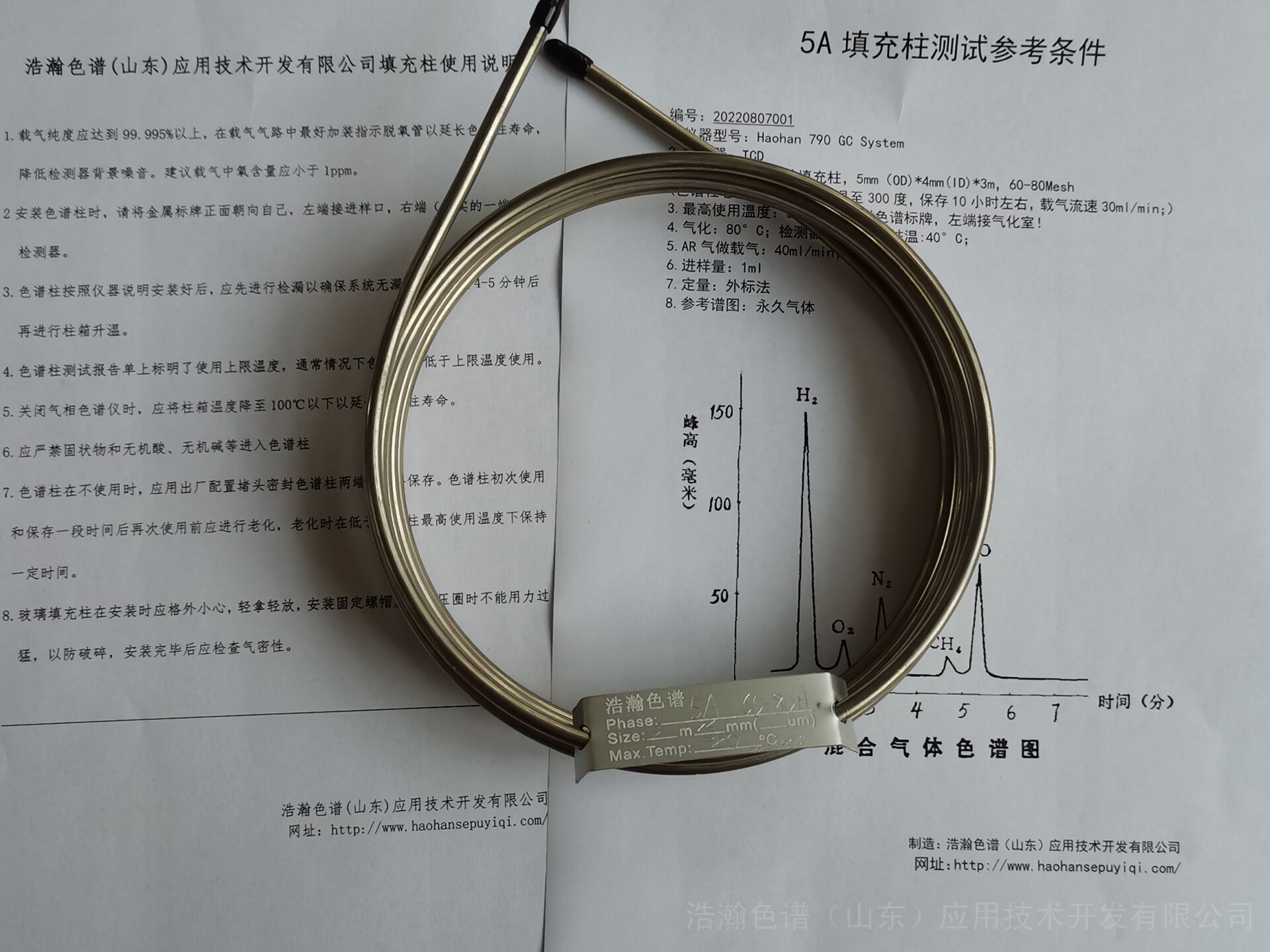

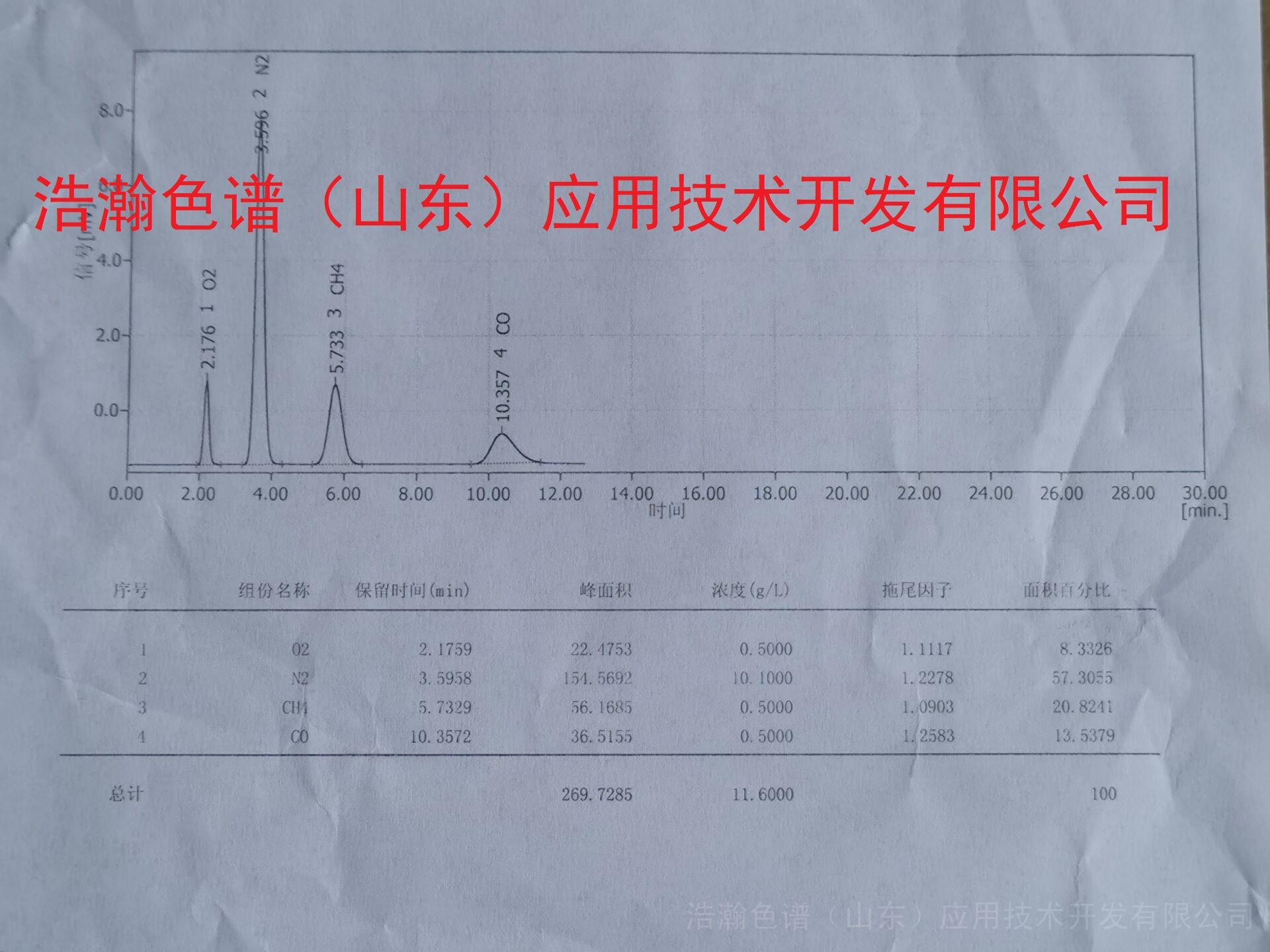

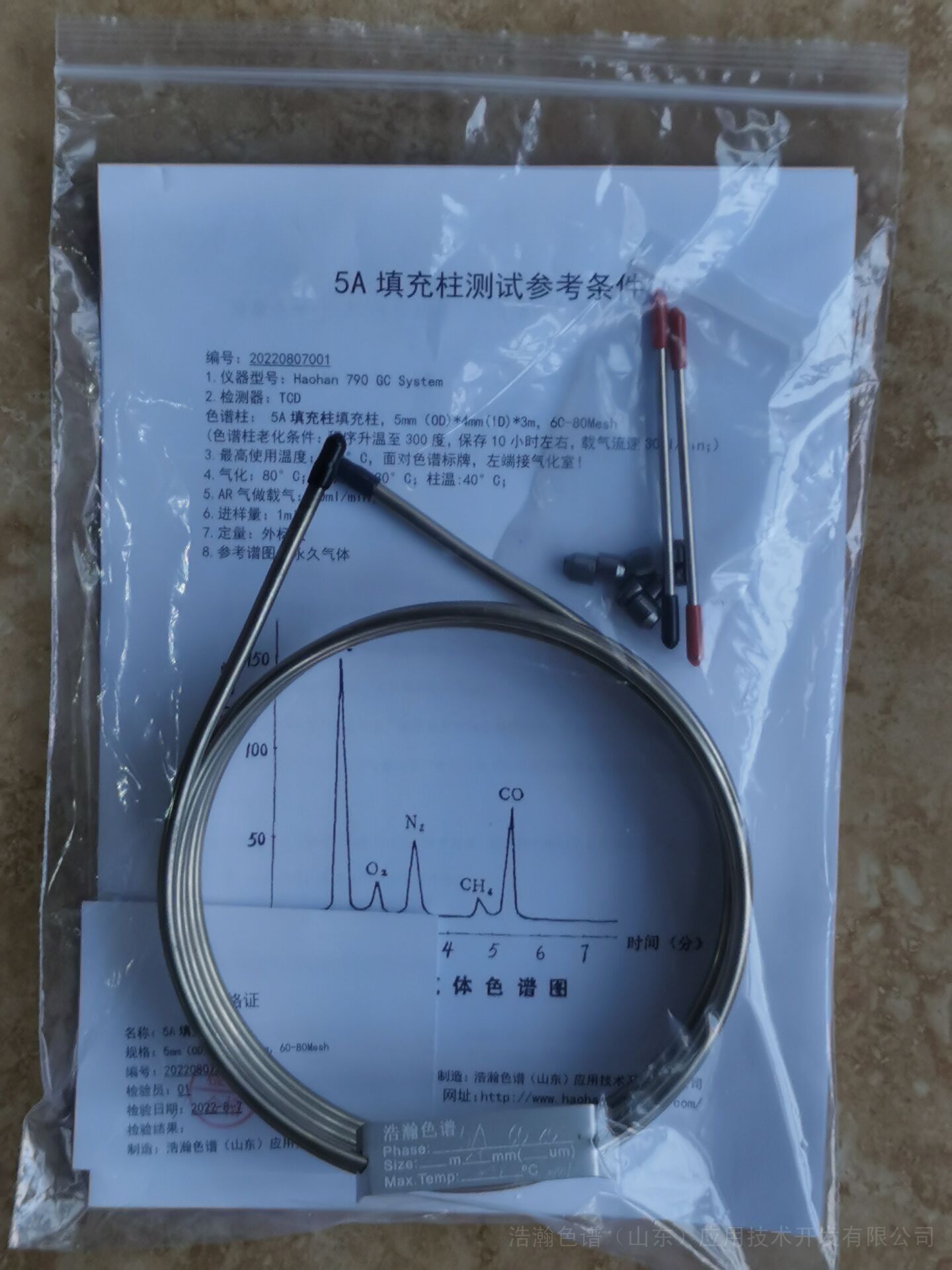

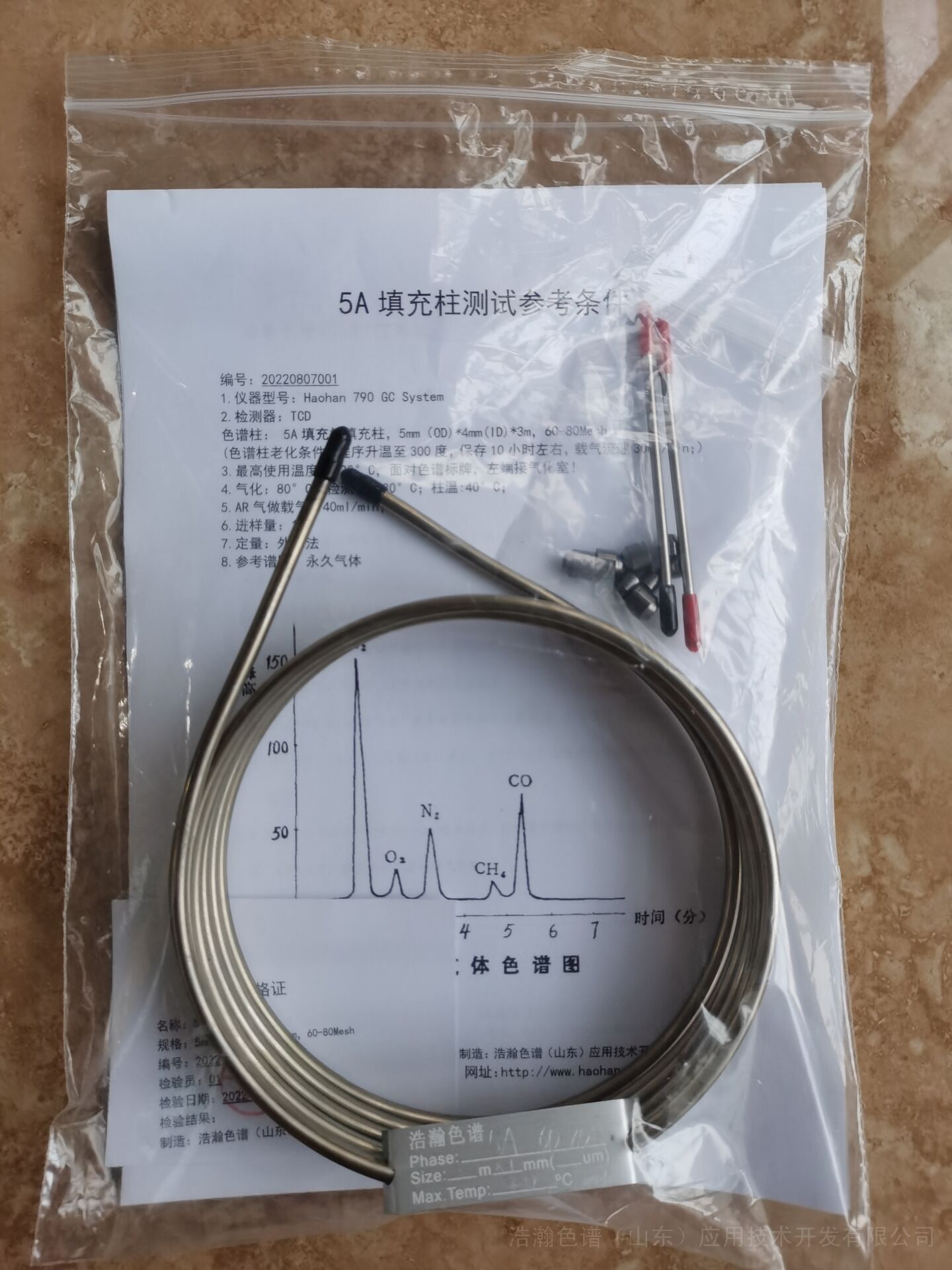

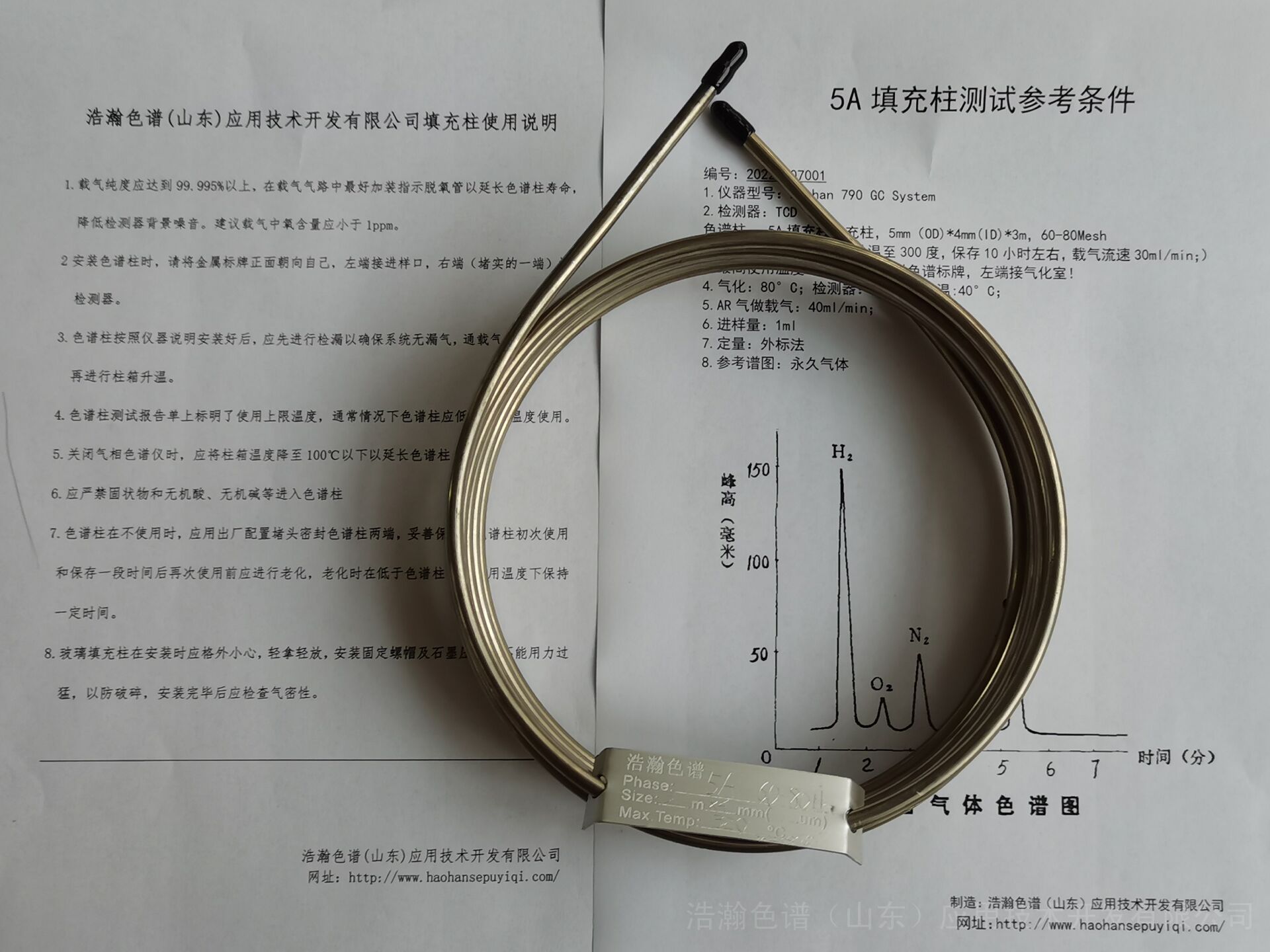

名称:5A填充柱

规格:5mm(OD)*4mm(ID)*3m,60-80Mesh

使用温度:320°C

编号:20220807001

应用:药典氧,氮,一氧化碳,甲烷的测定

Molecular sieve pressure swing adsorption utilizes the difference in the adsorption capacity of molecular sieve for oxygen and nitrogen and the characteristic that the adsorption capacity changes with the change of adsorption pressure to produce medical oxygen for the purpose of medical treatment and health care. It has the characteristics of cleanliness and easy access. In order to obtain breathing oxygen simply and conveniently, a miniature oxygen generator for yi was designed by using the molecular sieve pressure swing adsorption principle. Methods: Based on the analysis of the work flow of the molecular sieve oxygen production equipment, the detailed gas circuit and circuit design of the equipment were given. After three-stage filtration treatment, the raw material air is pressurized by an oil-free air compressor and cooled by a condenser, and then enters the adsorption tower equipped with molecular sieve through a reversing control valve. Nitrogen, carbon dioxide and water vapor in the air are selectively adsorbed by the adsorbent. Oxygen passes through the adsorption tower and enters the oxygen storage tank, and is output as product gas after concentration, flow and pressure detection. The single-chip microcomputer is used to control the reversing switching of the reversing valve regularly, and the process of pressurized adsorption, pressure equalization and desorption is realized. The functions of signal detection, human-machine information interaction, fault diagnosis and alarm system during the operation of the equipment are also designed. Results: The oxygen concentration of the product was above 90%, and the concentration could reach 96% at low flow output. The noise of the whole machine is below 55dB, and it has functions such as timing, alarm, blood oxygen and pulse rate detection, and atomized drug delivery. Conclusion: With reasonable selection of equipment components, control devices and innovative structural design, the oxygen generator has stable oxygen concentration and pressure, low noise, high cost performance, and safe and reliable operation.

Name: 5A packed column

Specifications: 5mm(OD)*4mm(ID)*3m, 60-80Mesh

Operating temperature: 320°C

No.: 20220807001

Application: Determination of Pharmacopoeia oxygen, nitrogen, carbon monoxide, methane